Today I have come across the interesting repair solution which I decided to share with you guys so you know how to proceed if you ever come across something like this (which I am sure some of you guys will eventually if you are in the heavy duty truck repair industry). I have been called for emergency truck repair coolant leak on one of this newer Freightliner Cascadia equipped with a Cummins X15 engine.

The coolant leak was coming from a 90* brass elbow fitting on a passenger side that supplied coolant to a cab heater core.

As can be seen from a picture the fitting was resting on a truck’s frame for prolonged amount of time, which eventually caused it fatigue and breakage.

The wear on a fitting (almost if someone would work the surface with a file) tells a lot about the nature of exposure of this failed part. Basically, as can be seen from a picture, the truck’s frame shaved the part of the fitting off and after final shake after the engine shut off it finally gave out and broke. Needless to say, that due to this breakdown, truck lost almost all of his coolant and company’s driver could not complete his route as was scheduled. The intrigue moment of this repair was not to do the repair, but to complete the repair in a way that will prevent the reoccurrence of same issue of coolant fitting breakage in a future. I realized that the repair task must include the remedy and address Freightliner manufacture’s assembly plant fault or Cummins engineer’s error. As soon as the remains of coolant were drained and the broken elbow fitting was taken out with prior removal of a couple of hoses that were on a way I have headed to a Freightliner dealership for parts, thinking that they have some kind of upgraded fitting already available and engineers already addressed this issue. Initially I have thought that the remedy will consist of basically the similar fitting, but with lesser length of a smooth portion of it to clear the frame. Ideally, the size of that fitting should have been no more than 1.5″ in it’s greatest width. However, after talking to a couple of Parts guys, explaining the issue which I was dealing with, and showing them detailed pictures, I have realized that not only is there an available solution, but they have never heard about this part failing off or came across it. Moreover, there was no readily available “improved” fitting I could just buy and install to clear out the frame. Also, I have spoken to a couple of Freightliner dealer techs, none of which dealt with similar issues, but all of them concluded that there is definitely a manufacture’s defect of placing the fitting literally “right on a frame”. Also, unfortunately, at that day in a shop bay was not a single Freightliner Cascadia with the same X15 engine for comparison and possible check of how the other X15 might of came up with. The only part that was available to me for a repair was the one I have a picture of (basically the same elbow, but with even longer smooth portion of a fitting, which in fact will rest above the frame the same way if not worse than the original one). I also had a chance to speak to a Freightliner Service Manager Lance Smith and I have suggested to him that this could potentially be the Cummins manufacture’s fault I am dealing with and final Assembly Plant should not allow something like this to happen, since this setup will eventually lead to a failure. It is quite obvious, that due to the nature of operation of diesel engine there is a lot of vibrations (caused by unequaled inertia forces) involved and this fitting literally was “sitting” on a frame thus hitting it constantly during engine operation, moreover during firing up and shutting down processes.

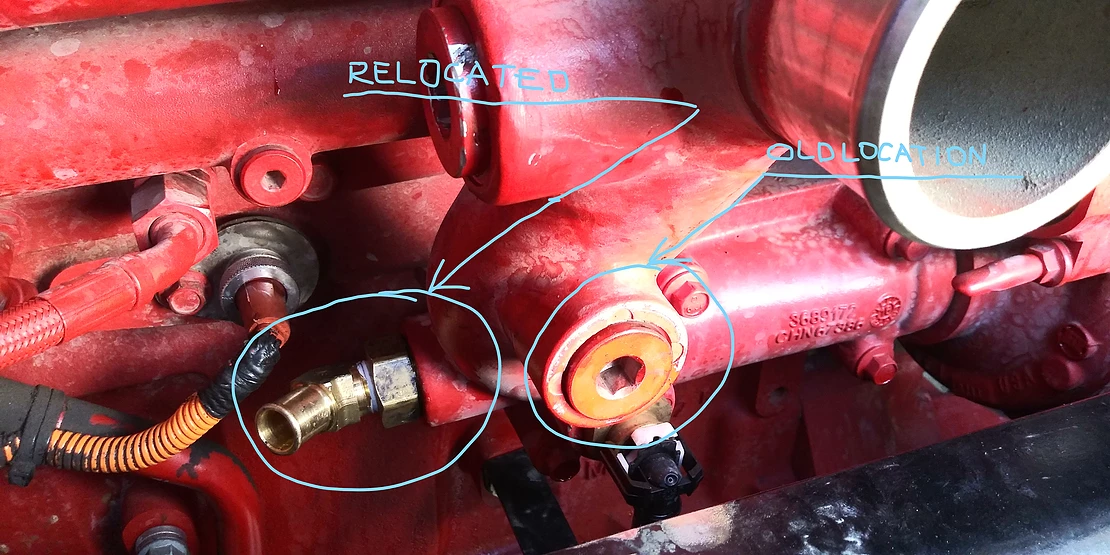

Mr. Smith agreed with me about very poor location of coolant fitting and suggested that if the truck was at Freightliner dealership facility, he could have addressed the issue with Freightliner Engineers, but in my case been an independent mobile truck repair company, there is “no access” to a process of submitting the report to them. Also, after carefully reviewing the pictures I have taken and listening patiently to my suggested solutions to this issue Lance suggested that probably this heater core hose was wrongly routed to fit this particular frame due to a different X15 engine applications and proposed to relocate a broken fitting in a different threaded opening in a coolant manifold and instead of that open bore put the plug that was taken out off that other opening.

That was a great idea and I thought the only one feasible in this situation!!! Before I have spoken to Lance I even though of notching a bit of a frame out to accommodate a new (same as old broken one) fitting. I ended up buying a couple of fittings (one 90* and the other one 135*), plenty of coolant and headed back to stranded truck I was working on in a field.

Upon my return I have pulled out the plug that Lance suggested and which could accommodate the new 90* fitting, but that plug was way bigger than the fitting I needed to install and could not fit there. Below are the pictures of a comparison between the plug taken out from a front of manifold and the other one I have ended up took out. I have looked very carefully at other possible locations for the fitting on a coolant manifold to relocate my fitting and finally found it. Way at the bottom (facing towards the firewall) I have found the plug of the same diameter as my fitting was to thread in to with the same pitch and bolt diameter, took it out and installed my fitting in along with a 135* elbow fitting. That was the moment of TRUTH!!!

Everything went in perfect; all fittings and hose clamps were torqued down and coolant filled up into the reservoir. After idling a truck for several minutes and getting it to operational temperature the coolant system was bled out of air and truck was released to the driver. Repair complete!!!

To finalize this article, if any of you guys come across this issue with broken brass 90* elbow fitting on a pass side where it is joints the coolant manifold and picks up the hose for the heater core the pictures clearly show the location where to relocate it and what parts to get in order to prevent the same issue, breakdowns and downtime in a future. Should the fitting will not be relocated as per this right up – the same problem will return sooner rather than later. Also, due to the nature on assembly process any fitting with more than 1” will not clear the frame and would be simply impossible to install. In this repair just like in any others always try to see a “bigger picture” and try to understand why did the failure happened in the first place. Was it the bad design of a component, faulty material component made out of or maybe simply the wrong placement of a component? I am sure that this approach will not only improve the quality of repairs, but also will improve the fault troubleshooting thinking process of technicians in future repairs.

TAGS: cummins repair, repair truck, semi truck repair, sacramento truck repair, help onroad.